( لطفا برای ملاحظه

مشخصات هر پروژه

بر روی آن کلیک کنید )

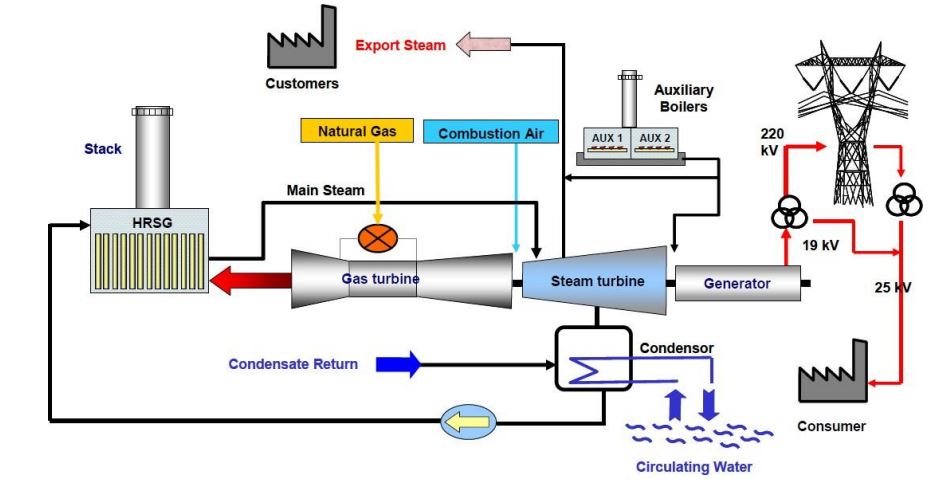

نیروگاه 400 مگاوات سیکل ترکیبی شامل یک واحد گازی 260 مگاواتی مدل GE Frame9A و یک واحد بخار 138 مگاواتی GE D-10A می باشد .

این نیروگاه دارای مشخصات فنی زیر می باشد :

Project Milestones

• Start of construction 15th of July 2001

• First firing 8th of May 2003

• First synchronization 26th of May 2003

• Commercial Operation 19th of December 2003

Objectives

• Electricity production: 385,9 MW

• Steam Export: Max. 150t/h a 30 bar and 260°C

• Demin. Water Export: Max. 70m3/h at 0,2µS/cm

• Electricity Export: Max. 200MVA at 25K

Nominal Operation Parameters

• Nominal Power Output: 400MW

• Auxiliar Consumption: 3,0%

• Net Efficiency (LHV): 55,6%

• Cogen Steam Mass Flow: 150 t/h

• Natural Gas Consumption: 54.469kg/h

• Fuel Oil Consumption: 65.251 kg/h

Power train maintenance as per manufacturer scheme (GE)

Last major overhaul September to November 2011 Operation facts

• Running 47.188,3 hours (gas fired), 103,7 (gas oil fired)

• Star ups 414

Operation facts from las overhaul

• Running 500,2 hours

• Start ups 30

Conservation plan for components

• Powert train: in forcé as GEscheme

• Rest: as per internationalstandards

Administrative status

• Closed from November 2017

Single Shaft

Configuration

• • • • • • •

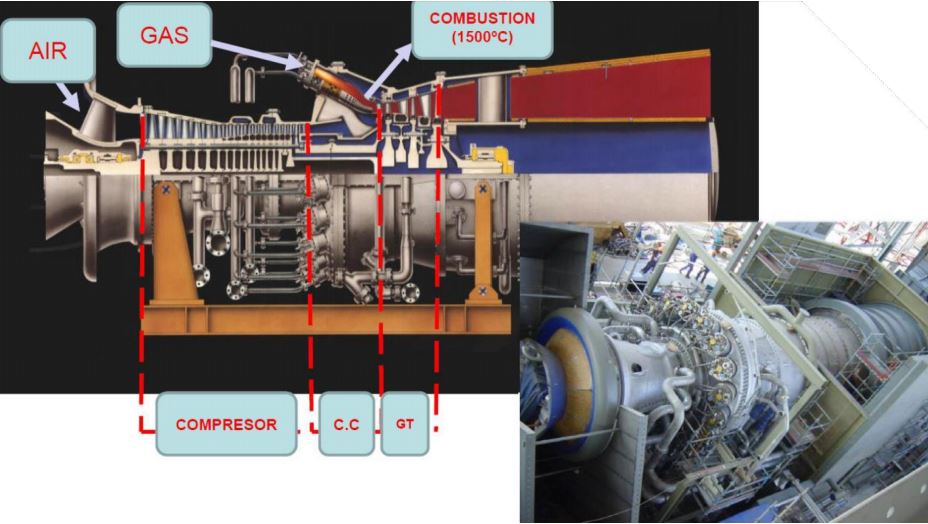

Manufacturer: General Electric

Model: 9FA+e

Power Output: 260 MW

Compressor: 18 Stages

Turbine: 3 stages

Exhaust Mass Flow: 614 kg/s

Exhaust Temperature: 620°C

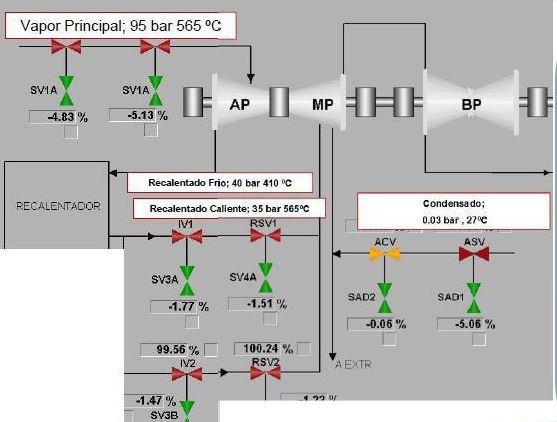

Steam Turbine

• • • • • • • •

Manufacturer: General Electric

Model: D-10A

Power Output: 138 MW

HP Steam Turbine: 9 Stages IP

Steam Turbine: 11 stages BP

Steam Turbine: 6stages

Turbine By-pass: Automatic to condensor

Main Steam: HP 90 bar at 565°C

IP 34 bar at 565°C

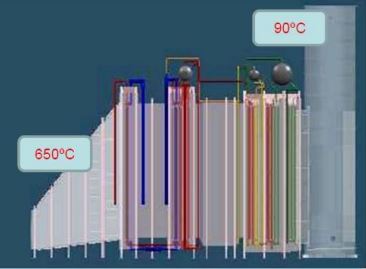

HRSG

• • • • • • •

Manufacturer: Astom Power Boilers

Model: GR-0960

Configuration: 3 pressure

HPSH Steam: 83 kg/s at 95bar and 565 °C

IPSH Steam: 6,3 kg/s at 37bar and 540 °C

Reheat Steam: 86,3 kg/s at 35bar and 565 °C

LPHS Steam: 14 kg/s at 4bar and 297 °C

Generator

• • • • • • • • •

Manufacturer: General Electric

Model: 390 H

Connection: Star

Power : 468 MW

Refrigeration: Hydrogen

Voltage: 19 kV ±5%

Cos ф: 0,85

Intensity: 13.582 A

Frequency: 50Hz (3.000 r.p.m.)

Auxiliar Systems

Control System

Environmental

Aspects

مرجع خاص

نیروگاه 400 مگاوات سیکل ترکیبی شامل یک واحد گازی 260 مگاواتی مدل GE Frame9A و یک واحد بخار 138 مگاواتی GE D-10A می باشد .