( لطفا برای ملاحظه

مشخصات هر پروژه

بر روی آن کلیک کنید )

این نیروگاه 77 مگاواتی شامل یک واحد گازی 44 مگاوات GE FRAME 6 و یک واحد بخار 33 مگاوات ABB می باشد

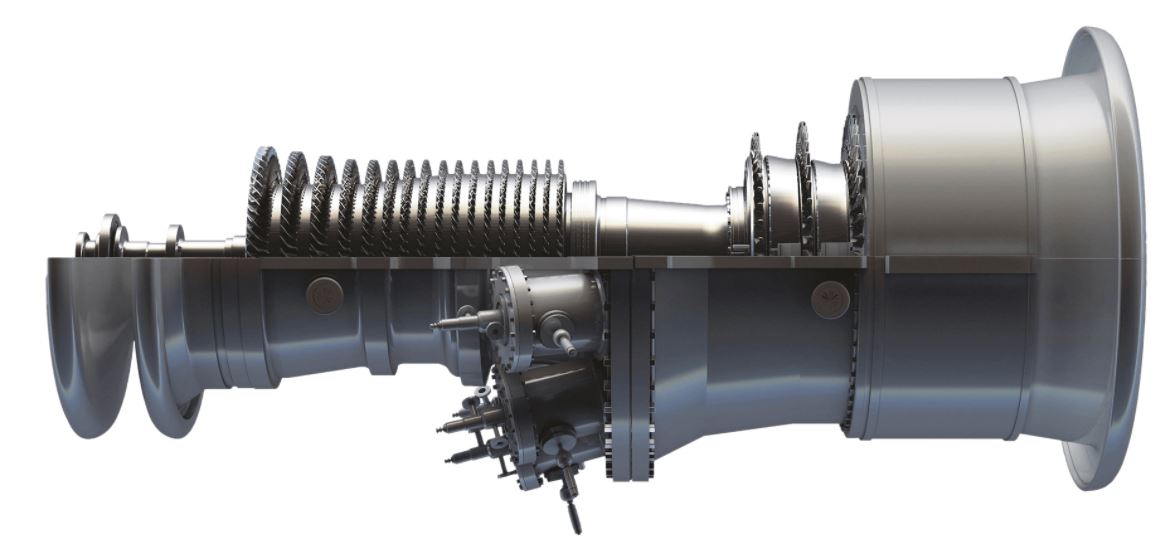

77MW CCGT (50HZ) Frame 6B (PG 6561B)

Frame 6 B gas turbine PG 6561B, LEC upgraded one, converted in 2009 from Syngas to LEC natural gas combustion system

GT transmission

Generator Alstom T 214-234

GT controller system (Mark V)

Co2 fire extinguishing system of the gas turbine

Heat recovery steam generator, standard boiler Duisburg 4x4 sygas-fired additional burner

Main steam turbine, double extraction - contensation turbine

ABB Turbine Nürnberg GmbH, type VEE 40

Boiler feed water pumps 1 and 2 Sulzer Pumps Germany

Contensation steam turbine SST 060, Siemens Turbomachinery

Cooling water pumps 1 and 2 and 3 KSB AG Dt.,

Cell cooling turbine 1 and 2, GEA Energietechnik GmbH

Full desalination plant 2.9 sqm, Hager and Elsässer GmbH

this also includes:

Housing gas turbine generator set with filter house

Gas turbine machine transformer 10/30 KV; 55 MVA, Pouwels

Heat recovery steam generator with gas turbine - flue gas duct and chimney

Machine house - steel structure, isopanels

Steam turbine machine transformer 10/30 KV; 37.5 MVA

both cell coolers

Gas reducing station - without the building itself

Double girder overhead traveling crane 25 to. and 6.3 tons,

Elevator boiler house 500 ZPP, GEDA -

During the conversion of the GUD to natural gas, the following work was carried out on the main units

Gas turbine

Hot gas path inspection

Exchange of the 10 transition pieces

Exchange of the 10 burners with Wueruündrphren

Exchange of the guide u, blades of all 3 stages

Installation of a LO Nox system

Adaptation of the control to the new driving style (software change)

Transmission revision

Refilling the turbine oil

In 2010 a 3-stage air filter was installed

Gas turbine generator

pull large revision with inductor

Insulation measurements

The conversion of the GT was carried out by Ansaldo Thomassen.

Steam turbine

open the turbine

Bring runners to the factory, material tests, blasting, sheet metal, balancing

Reseal parting joint

Close withdrawals that are no longer required

Realignment of the runner

Renewal of sealing steam control

New turbine control and adaptation to the steam turbine generator control system

The same work was carried out on the generator as on the GT generator.

The revision work was carried out by Turbomaschinen (TMS).

Waste heat boiler

The AHK received a water pressure test

Comprehensive material tests were carried out

All TÜV-relevant tests including the associated containers and pipelines

مرجع خاص

این نیروگاه 77 مگاواتی شامل یک واحد گازی 44 مگاوات GE FRAME 6 و یک واحد بخار 33 مگاوات ABB می باشد